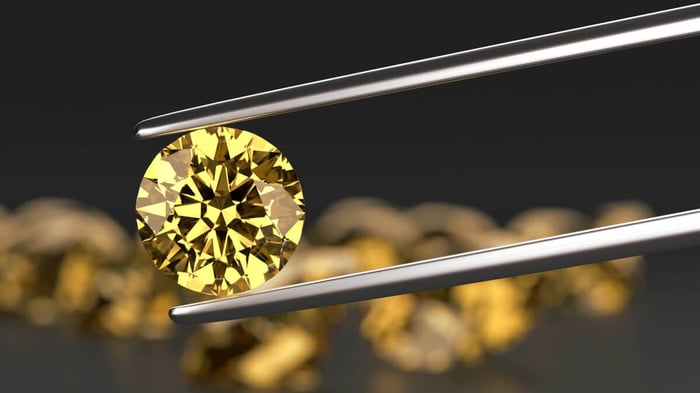

Learn About How A Diamond Is Cut And Why The Quality Of Diamond Cutting Is So Important

When a diamond is mined or found in river deposits, it looks nothing special. A rough diamond looks like a grey pebble. Its beauty can be revealed and appreciated only when the diamond is cut and polished. The process of taking these nondescript pebbles and turning them into the fiery, brilliant gemstones that we love so much is a highly skilled craft. Diamond cutting and polishing techniques have been developed over hundreds of years. They have reached a peak of refinement in the past fifty years with the introduction of computerised design tools to create ever more brilliant diamonds and high-speed saws and lasers to cut more delicate facets into the rough diamond.

In this article, we will take a brief look at the process of diamond cutting and polishing as well as how experts assess the quality of diamond cutting.

When it comes to diamond jewellery, one of the characteristics regarded as being the most essential to the eventual quality of the finished piece is the quality of the cutting and polishing, often referred to as cut quality. The quality of the cutting and polishing of the finished gem can make up for a worse colour quality or a generally inferior clarity. This process of balancing and compromise is called "offsetting."

On the other side, if the stone's cut is subpar, it will not live up to its lofty promise of being a D-color, internally flawless stone. This is because D is a very high colour grade. Because of the poor quality of the cut, the diamond will not have as much brilliance, sparkle, or scintillation as it would if the cut quality were better.

Halo Cluster Heart Necklace 0.40ct G/SI Diamond in 18K White Gold

£677.00

£957.00

The classically romantic heart shape, made with ethically sourced, sparkling diamonds then framed with a diamond halo and set in striking 18k white gold for an eye-catching sparkle and shine. Our UK craftsmen have pride and confidence that this will… read more

A Very Short History Of Diamond Cutting

Diamond cutting technology has moved past mechanical cutting tools and on to laser cutting for very high accuracy and consistency. Since the commencement of diamond cutting in the mid-13th century, techniques have developed to become what they are today. The discovery that a greater number of facets resulted in a more brilliant stone took place in the 1600s. Today, diamond cutters can create ever more brilliant designs with computer-aided design techniques.

The single cut was the basis for developing the contemporary and widely used Brilliant cut. The modern round brilliant cut diamond has developed into a circular contour, symmetrical triangular and kite-shaped facets, a table, and a small culet, which was optional. In addition, the modern round brilliant-cut diamond had a table.

The Diamond Cutting Process

Even though there are only five primary procedures, cutting a diamond is rather lengthy and laborious. For the average person, understanding a little about the tedious processes is necessary to appreciate the effort that has gone into making a nondescript stone into a piece of sparkling beauty.

Diamond Shapes Come From Different Shaped Rough Diamonds

The form of the finished piece of diamond jewellery is determined, in large part, by the inherent contours of the raw stone from which it was cut. The marquise, oval, or pear form is achieved by cutting naturally elongated stones. Round diamonds are cut from more spherical rough diamonds.

There is a possibility that there may be almost perfect crystal forms, and those crystals will most likely be cut into princess cuts or other square designs. Because of the risk of wasting the rough diamonds used in the cutting process, the planning process for certain big stones might take significantly more time. Skilled diamond cutters can often cut two diamonds out of a single rough stone.

Planning The Diamond Cutting

The first critical step in making diamond jewellery is planning. Here the cut planner will carefully inspect the rough stone and mark it to indicate where the cutter should make the cuts to create the final cut diamond. One of the cut planner's goals is to reduce the amount of wasted diamond material. Sometimes this might mean a diamond is not cut with absolutely perfect proportions. Compromising the ideal cut can cause problems with diamonds that rely upon perfect symmetry for maximum beauty, such as pear and heart shapes.

When marking, the planner chooses the crystal based on its size, clarity, and direction it will face when set into a piece of jewellery. The planner identifies the cleavage planes along which the diamond will tend to break. This stage enables a larger rough diamond to be cut into smaller pieces, but if he gets this task wrong, the diamond could shatter and become worthless.

Errors of any kind, including inaccurate marks and others, can result in expenses reaching thousands of pounds.

Cleaving And Sawing

Following the marks made by the planner, the stone is either manually cleaved or sawn to create the desired shape. A diamond can be shattered and rendered worthless if it is cleaved in the wrong spot, meaning that both the cut planner and cutter have a huge responsibility to get it right! The diamond cutter will use a diamond-coated rotary saw or a laser to form the diamond into shape.

Next, the cutter uses a laser or mechanical saw to cut a groove into the diamond. Then the diamond is split along the groove with a steel blade. This highly skilled process creates the initial shape of the diamond.

Diamond Solitaire Necklace 1.00ct G/SI in 18k White Gold

£2,997.00

£5,397.00

This beautiful and elegant diamond solitaire necklace is a great gift for any occasion. This versatile piece is perfect for casual or formal wear and can be worn with any outfit. This stunning and fashionable piece is made from 18k… read more

Diamond Bruting

The most popular diamond shape, the brilliant round cut, was only made possible by the introduction of the bruting machine in the early 1870s. Until then, there was no reliable way to cut a perfectly round shape. Bruting is a procedure in which the worked-on diamond is spun on a spinning lathe while another diamond is pressed against it to produce the finished diamond's girdle by grinding away excess diamond material.

Polishing The Diamond's Facets

At this point in the diamond cutting process, the stone is almost in its ultimate form, and its dimensions are finalised. Here, the diamond cutter places the polished facets onto the previously created shape.

The initial step in the polishing process is called blocking. This work lays the groundwork for the diamond's fundamental symmetry. It is here where the first 17 or 18 facets of the cut are created, making this the beginning of the process. At this point, the procedure for extremely small diamonds ends. Larger diamonds still need more work.

Diamond 'Brillianteering' – Where The Sparkle Comes From!

The "brillianteering" step, in which the bigger diamonds' last facets are polished, comes next in the production process. The type, number and quality of the additional facets will decide the brilliance and fire of the finished diamond, as well as whether or not they will be sparkling beauties or stone-like relics.

The cutter's goal is always to produce a masterpiece of diamond jewellery - this is what keeps them going.

Diamond Cut Quality Grading

Diamond quality is assessed by experts working in grading labs using four criteria called the 4Cs: Colour, Cut, Clarity and Carat weight.

Almost all grading labs around the world use the same criteria. However, the grading standards can vary from one lab to another, with the GIA being recognised by most experts as providing the most consistent and highest-quality diamond grading reports.

Many people regard cut quality as the single most crucial factor that decides the eventual quality of the sparkle and brilliance of a diamond because this is the only factor under humans' control rather than being an accident of nature.

Cut grade is rated using a scale of four levels: Poor/Fair, Good, Very Good, Excellent. In most cases, a Good or better cut quality grade will result in diamonds that look absolutely satisfactory, and Very Good or Excellent cut grade diamonds can fall outside the budget of many consumers. Avoid gemstones with a cut grade of Poor/Fair when you buy a diamond.

20 Baguette Diamonds Half Eternity Ring 0.75ct 18k Yellow Gold 4.0mm

£1,377.00

£2,107.00

A solidly imposing half eternity ring still retains sensual femininity with the sparkle of three-quarters of a carat of hand-cut, baguette-shaped diamonds in a channel setting on a glossy 4.00mm width yellow gold band. The diamonds used are conflict-free and… read more

All Diamond - Quality Diamond Jewellery At Great Value Prices

We are proud of all the diamond jewellery we sell at All Diamond. Each piece is designed and handcrafted here in the United Kingdom. Every piece of jewellery carries a lifetime workmanship guarantee.

Now that you know a little more about how a diamond is cut, turning dull grey pebbles into brilliant sparkling gemstones, you can better appreciate the skill and care that makes our beautiful jewellery possible. Buyers of our diamond jewellery can enjoy brilliance and sparkle that not even emperors and kings could have enjoyed 200 years ago. There has never been a better time to enjoy these gorgeous gemstones!

Please take a few minutes to browse through our carefully designed diamond jewellery collections to suit all tastes and budgets. We are confident that what you see will inspire you to make an excellent choice for your next fine jewellery purchase!